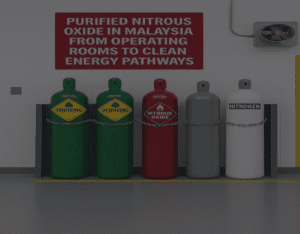

Argon is one of the most widely used inert gases across Malaysia’s industrial sectors. From precision welding to semiconductor production, the demand for purified argon Malaysia continues to rise as industries prioritise quality, efficiency, and safety.

Whether used as a shielding gas, filling gas, or laboratory-grade inert atmosphere, the purity level of argon directly affects product quality and operational consistency. In this article, we explore why purified argon is crucial, the industries that rely on it, purity grades available in Malaysia, and how AGS supplies compliant, high-purity gas solutions nationwide.

What Is Purified Argon and Why Does Purity Matter?

Purified argon is argon gas refined to remove impurities such as oxygen, nitrogen, moisture, hydrocarbons, and other trace contaminants. Depending on application, purity can range from 99.99% (4.0 grade) to 99.9999% (6.0 grade).

Why purity is critical:

- Prevents oxidation during welding

- Ensures consistent laboratory results

- Supports defect-free semiconductor processes

- Maintains reliability in metal fabrication

- Improves efficiency in 3D printing and laser applications

Industries in Malaysia That Rely on Purified Argon

1. Welding & Metal Fabrication

Purified argon is indispensable for TIG and MIG welding, especially for stainless steel, aluminum, and titanium.

- Provides a stable arc

- Reduces spatter

- Improves weld bead appearance

- Prevents porosity caused by oxygen contamination

2. Electronics & Semiconductors

Malaysia’s strong electronics sector requires ultra-high purity argon for:

- Wafer processing

- Solder reflow

- Plasma etching

- Controlled inert atmospheres

3. Laboratories & R&D

Used in gas chromatography, mass spectrometry, and inert sample handling. Even small impurities can alter scientific results.

4. Additive Manufacturing (3D Printing)

Argon provides a stable, oxygen-free environment for metal powder fusion — essential for aerospace, automotive, and medical components.

5. Food & Beverage Packaging

While nitrogen is common, purified argon helps extend shelf life by displacing oxygen more effectively in certain niche applications.

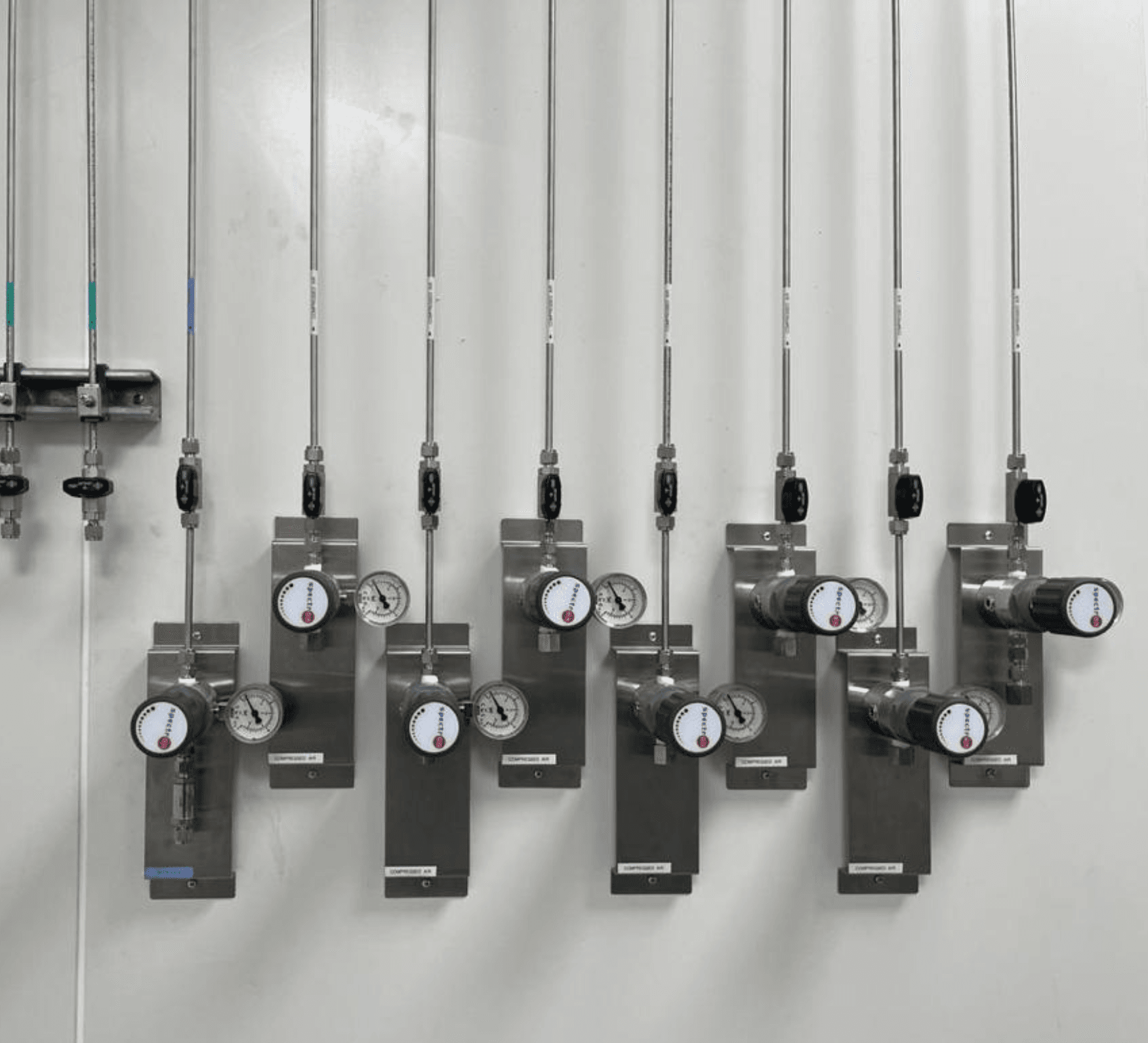

How AGS Ensures Reliable Purified Argon Supply

As one of Malaysia’s trusted gas suppliers, AGS (Alpha Gas Solution) provides consistent, certified, and safe purified argon solutions for all industry sizes.

AGS advantages include:

- DOSH-certified cylinders and filling processes

- Purity verification via batch analysis

- Secure storage and transportation compliance

- Milk-run delivery routes for steady supply

- Technical support for welding and industrial clients

Safety Tips When Handling Purified Argon Cylinders

Even though argon is inert, safe handling is essential:

- Always store cylinders upright and chained

- Keep storage areas ventilated

- Use the correct regulators for purity grade

- Avoid confined spaces without gas monitoring

- Perform leak checks before use

These practices help prevent asphyxiation risks and ensure smooth operations.

Why Choose AGS for Purified Argon in Malaysia?

AGS stands out for its commitment to:

- High-purity standards for consistent output

- Fast delivery across industrial zones and major cities

- Affordable cylinder rental and refilling

- On-site consultation for welding and manufacturing setups

Clients from manufacturing, healthcare, and electronics industries rely on AGS for dependable and certified gas supply.

Conclusion

As industries advance, the need for purified argon Malaysia continues to expand, especially within welding, electronics, and laboratory sectors. High purity ensures precision, safety, and efficiency — all of which are essential for quality production.

With AGS providing reliable, certified, and cost-effective argon solutions, businesses are equipped to meet the increasing demands of modern industrial processes.