In laboratories, precision is everything—but so is safety. From oxygen to liquid nitrogen, improper handling or storage of industrial gases can lead to dangerous consequences. This guide covers five essential gas safety practices for research and medical labs—plus how Alpha Gas Solution (AGS) helps ensure safe, compliant gas usage across Malaysia.

🧯 1. Use Certified Gas Cylinders with Clear Labelling

- Always obtain cylinders from licensed suppliers (AGS is DOE-compliant).

- Verify label info: gas name, hazard class, expiry, and pressure rating.

- Store certificates digitally or physically for audit readiness.

🏗️ 2. Store Gases in Safe, Well-Ventilated Areas

- Separate flammables from oxidizers using color-coded storage.

- Secure upright with steel chains or brackets.

- Ensure airflow with exhaust fans and leak detectors.

🧑🏫3. Train Staff in Emergency & Leak Procedures

- Conduct fire drills involving gas valve shutdowns.

- Provide staff with Safety Data Sheets (SDS).

- Simulate common emergencies like slow leaks or pressure drops.

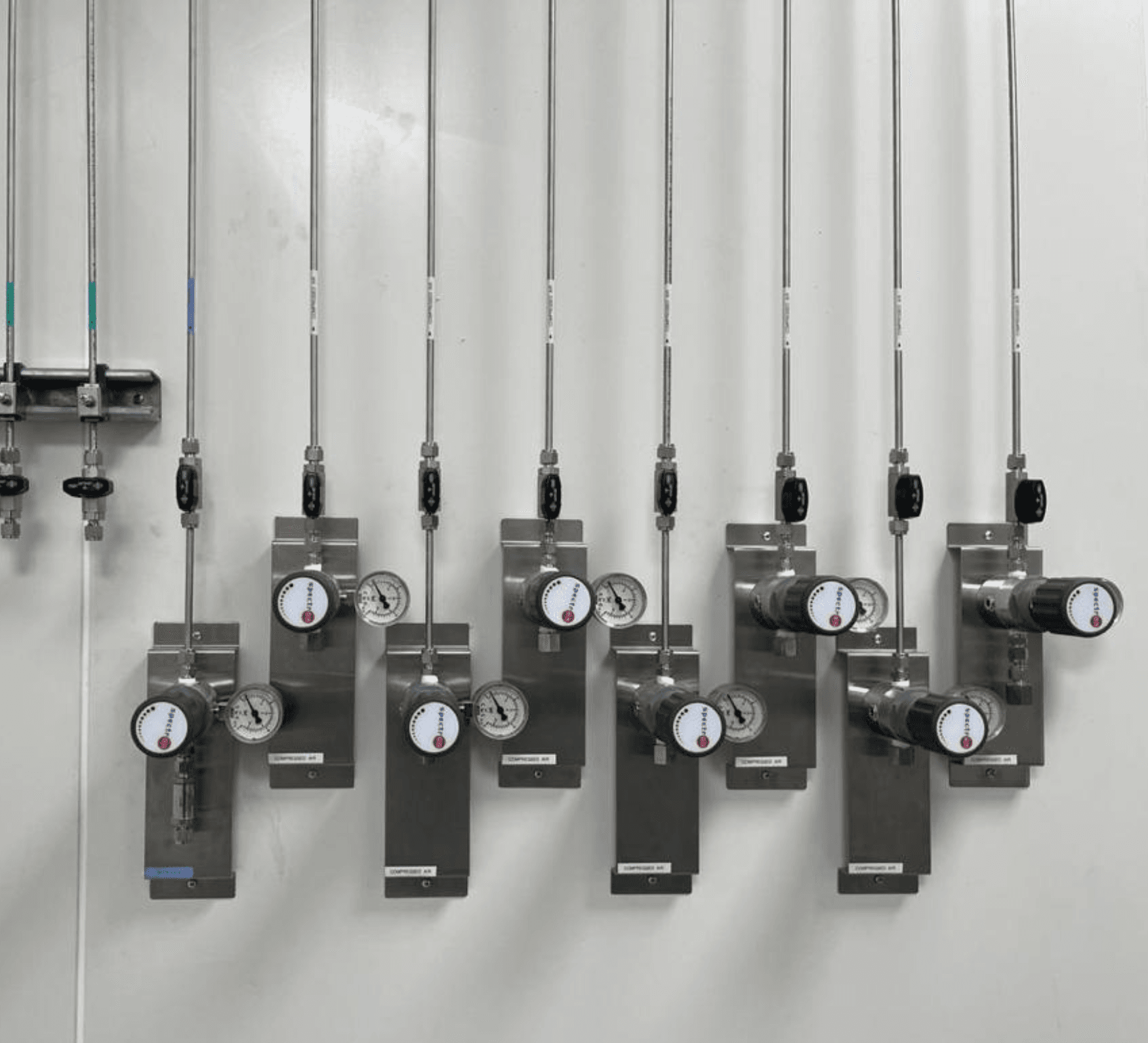

📊 4. Monitor Tank Pressure and Schedule Refills

- Use pressure gauges or digital sensors.

- AGS offers Milk-Run delivery to prevent shortages.

- Regular monitoring avoids lab downtime or sample spoilage.

🔧 5. Use Correct Regulators and Fittings

- Don’t mix equipment between gas types.

- AGS supplies matching regulators upon delivery.

- Check for wear, leaks, or loose fittings every 2 weeks.

🛡️ How AGS Helps Labs Stay Compliant

Alpha Gas Solution supports over 800+ Malaysian clients by providing:

- High-purity gas blends with proper safety documents

- On-site delivery and installation of cylinder racks and fittings

- Lab-specific safety audits and compliance tips

✅ Final Thoughts: Safety First, Always

With increasing demand for precision gases in medical, biotech, and academic research, it’s more important than ever to invest in safe gas handling. Whether you’re running a university lab or a private clinic, partnering with AGS ensures peace of mind, compliance, and uninterrupted performance.